Current location:Home > seal repair kit >

seal repair kit

2025-08-14 14:32

2025-08-14 14:23

2025-08-14 14:11

Another important feature of hydraulic lip seals is their ability to reduce friction and wear on the moving parts of the hydraulic system

hydraulic lip seal. By creating a tight seal between the piston and cylinder, these seals help to minimize the loss of hydraulic fluid and prevent contamination of the system.

hydraulic lip seal. By creating a tight seal between the piston and cylinder, these seals help to minimize the loss of hydraulic fluid and prevent contamination of the system.

...

2025-08-14 13:40

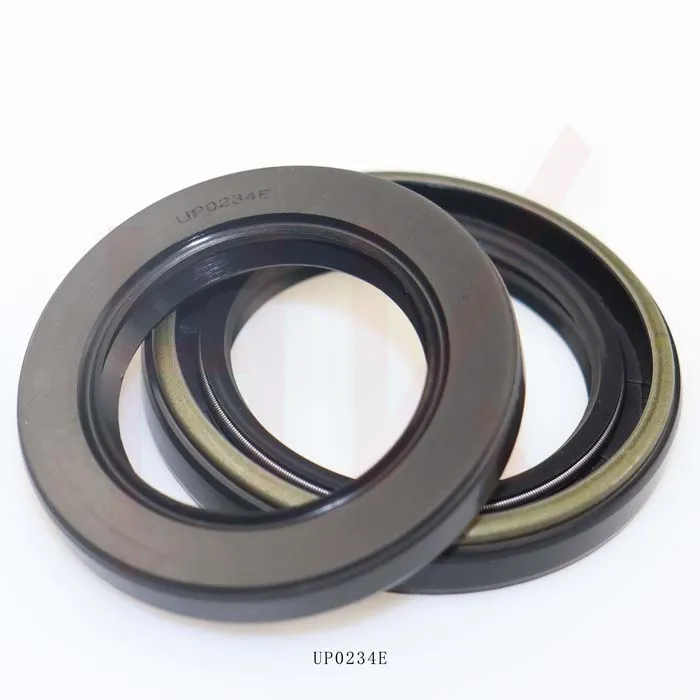

In addition to preventing leaks, oil seals also help to retain important lubricants within the machine, improving its efficiency and reducing wear on moving parts 38x52x7 oil seal. When oil seals fail, they can result in costly repairs, downtime, and reduced productivity. Therefore, it is essential to regularly inspect and replace worn or damaged seals to ensure optimal machine performance.

38x52x7 oil seal. When oil seals fail, they can result in costly repairs, downtime, and reduced productivity. Therefore, it is essential to regularly inspect and replace worn or damaged seals to ensure optimal machine performance.

38x52x7 oil seal. When oil seals fail, they can result in costly repairs, downtime, and reduced productivity. Therefore, it is essential to regularly inspect and replace worn or damaged seals to ensure optimal machine performance.

38x52x7 oil seal. When oil seals fail, they can result in costly repairs, downtime, and reduced productivity. Therefore, it is essential to regularly inspect and replace worn or damaged seals to ensure optimal machine performance.

...

2025-08-14 13:28

In addition to keeping out dirt and debris, dust wiper seals also help to retain lubricants within the machine. Lubricants are essential for reducing friction and wear between moving parts, and without proper lubrication, a machine can quickly become damaged and dysfunctional. Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently

Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently dust wiper seal.

dust wiper seal.

Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently

Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently Dust wiper seals help to seal in lubricants and prevent them from escaping, ensuring that the machine continues to operate smoothly and efficiently dust wiper seal.

dust wiper seal.

...

2025-08-14 13:07

2025-08-14 12:49

One of the key features of metal oil seals is their durability and resistance to wear and tear. Made from high-quality metal materials such as stainless steel, aluminum, and brass, these seals are able to withstand high temperatures, pressure, and friction without degrading. This makes them ideal for use in demanding applications where reliable performance is essential.

...

2025-08-14 12:46

2025-08-14 12:40

2025-08-14 12:34

Latest articles

The sealing lip is designed to conform to the shaft, creating a tight barrier that minimizes fluid escape

. Depending on the application, rotary shaft seals can be designed for various shaft diameters and operating conditions, including temperature extremes and high pressures.In addition to their functional benefits, oil seals also play a crucial role in extending the lifespan of machinery 14x24x6 oil seal. By preventing the ingress of harmful substances and maintaining the purity of the lubricant, these components help to reduce the frequency of maintenance and repair requirements. This not only saves time and money but also minimizes downtime, ensuring that machines can operate at peak efficiency for longer periods of time.

14x24x6 oil seal. By preventing the ingress of harmful substances and maintaining the purity of the lubricant, these components help to reduce the frequency of maintenance and repair requirements. This not only saves time and money but also minimizes downtime, ensuring that machines can operate at peak efficiency for longer periods of time.

14x24x6 oil seal. By preventing the ingress of harmful substances and maintaining the purity of the lubricant, these components help to reduce the frequency of maintenance and repair requirements. This not only saves time and money but also minimizes downtime, ensuring that machines can operate at peak efficiency for longer periods of time.

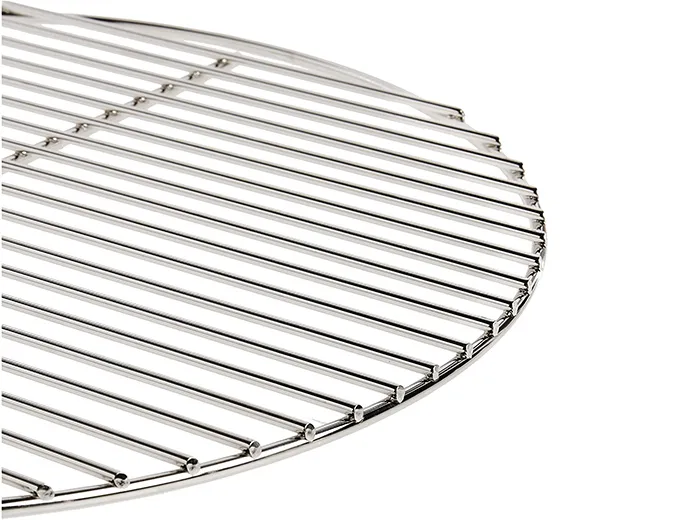

14x24x6 oil seal. By preventing the ingress of harmful substances and maintaining the purity of the lubricant, these components help to reduce the frequency of maintenance and repair requirements. This not only saves time and money but also minimizes downtime, ensuring that machines can operate at peak efficiency for longer periods of time.Moreover, the versatility of these grills is unmatched. While some models use charcoal for that classic smoky flavor, others are powered by propane, offering quicker heat-up times and even temperature control. There are even electric portable grills available, perfect for those camping sites that permit electrical appliances. This variety ensures that everyone can find a grill that suits their cooking style and needs.

little portable grill